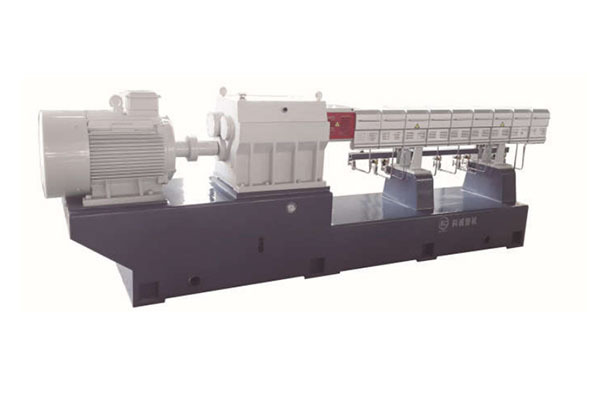

KC Series Co-rotating Twin Screw Extruder

Classification:KC Series Co-rotating Twin Screw Extruder

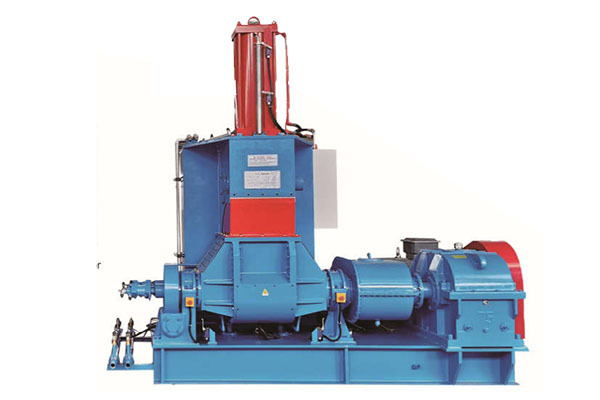

She mainly supply complete equipments for plastic & rubber compounding and pelletizingindustry,including dispersion kneader,parallel twin screw extruder, single screw extruder, variouspelletizers and other auxiliaries. They are widely applied in plastic modification, masterbatch, cablecompounds. rubber compounds, recycling plastic etc.

Key words:KC Series Co-rotating Twin Screw Extruder

Product Details

| Type | Series | D(mm) | L/D | N(r/min) | P(kw) | T(N/m) | T/A³ | Q(kg/h) |

| KC-20 | A | 21 | 32-48 | 600 | 4 | 30 | 4.8 | 2-10 |

| KC-36 | A | 35.6 | 32-48 | 600 | 18.5-22 | 125 | 4.6 | 30-75 |

| D | 600 | 30-37 | 225 | 8.3 | 40-100 | |||

| KC-52 | A | 50.5 | 32-64 | 500 | 45 | 405 | 5.1 | 120-200 |

| B | 600 | 45-75 | 415 | 5.2 | 155-255 | |||

| C | 500 | 75 | 565 | 7.1 | 200-355 | |||

| D | 600 | 75-90-110 | 680 | 8.5 | 255-400 | |||

| KC-65 | A | 62.4 | 32-64 | 500 | 55-75 | 680 | 4.8 | 200-355 |

| B | 600 | 75-90 | 680 | 4.8 | 255-400 | |||

| C | 500 | 110 | 830 | 5.9 | 300-550 | |||

| D | 600 | 160 | 1200 | 8.5 | 500-850 | |||

| KC-75 | A | 71 | 32-64 | 500 | 90-110 | 995 | 4.6 | 300-550 |

| B | 600 | 110-132-160 | 995 | 4.6 | 450-750 | |||

| C | 500 | 160-200 | 1200 | 5.5 | 500-850 | |||

| D | 600 | 250 | 1890 | 8.7 | 750-1250 | |||

| KC-95 | B | 92 | 32-64 | 400-500 | 280-315 | 2380 | 5.0 | 950-1600 |

| D | 550 | 4510 | 8.7 | 1650-2750 |

Application

Cable and Wire

PVC Series

LSFH

Insulation Sheath

Shield Cable

XLPE

Silane-crosslinked

Radiation-crosslinked

Rubber Cable

Fluorin Cable

Masterbatch

Carbon Black

Vhite

Pigment Masterbatch

Functional Masterbatch

Degradable Masterbatch

Fiame Retardants

Fiber

Polyreaction Extrusion

TPU

PI

POM

Fluoric-rubber

Silicon Rubber

Grafting Reaction

Degradation Reaction

Powder Coating

Polyester

Epoxy

Acryli

Filling Modification

CaCO3

Talc Powder

Barium Sulfate

Aluminium Oxide

TiO2

Ceramic Powder

Plant Fiber

Blending Modification

Rubber & Plastic

Plastic Aolly

Thermoplastic

Reinforcing Modification

Long Glass Fiber

Short Glass Fiber

Carbon Fiber

Other Fiber

Reactive extrusion

Profile Extrusion

Polymcr Rccyaling

Homogenization

Sllane-ketone Glue

Thermoset Plastic

Wood Plastic Composite

Mixing extrusion granulation equipment has significant advantages in chemical, plastic, rubber and other industries. It is characterized by high efficiency mixing, precise control, convenient operation and stable output. The equipment can ensure that the materials are fully mixed under high-speed stirring and improve product quality. At the same time, the intelligent control system can realize the precise control of temperature, pressure, flow and other parameters. Simple operation, reduce manual error. In addition, the equipment is suitable for a variety of materials, has strong adaptability, and can meet the needs of different industries. Widely used in the manufacture of PVC, PE and other plastic particles, as well as rubber, elastomer and other materials processing. Its efficient and stable performance has won wide recognition and praise in the industry.

Customer Message

Add: 21 Hexing Road, Nantong Economic Development Zone, Jiangsu, China

Tel:86-513-88788818

Fax: 86-513-88780855

Sales Service Hotline: 8615312925557 8618951318600 8618913245550

Website: www.kjcmach.com kjc. China

Mobile Site